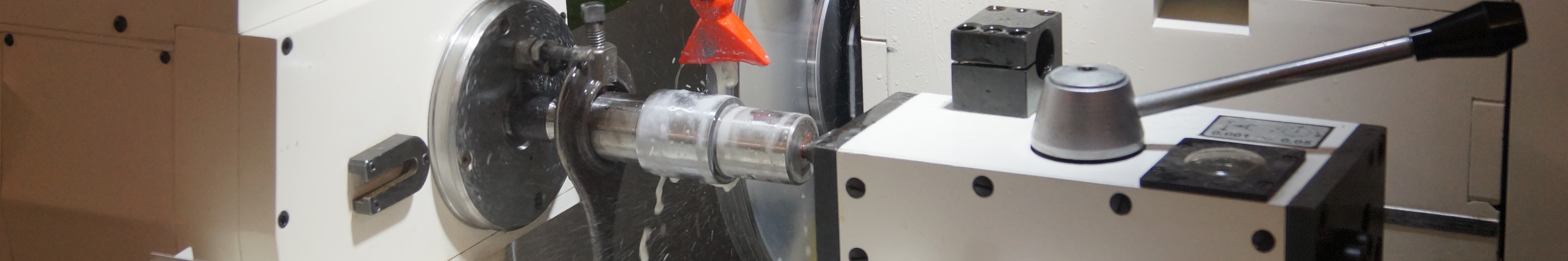

The BUA 25ST CNC grinder is a machine with significantly innovated design units to meet the most demanding requirements of our customers. We are able to offer the machine in both hooded and partially uncovered versions while maintaining the possibility of grinding in fully automatic or manual mode. Depending on the design, it can grind parts with a length of 630 (1000) mm and a diameter of up to 280 mm.

Základní informace

The basic version of the machine is ready for grinding with a grinding wheel with a width of 40 mm and a diameter of 400 mm while maintaining a constant cutting speed of up to 45 m/s. Equipping the machine with a hood has significantly increased the safety of the machine operator and the use of electrostatic extraction will also minimize mist leaks from the machine’s working area. The operator panel is equipped with a 15.6″ long life capacitive touch screen as well as mechanical buttons for confidence and ease of operation.

Of course, there is also a portable operator panel with an incremental positioning wheel for easier adjustment of the machine. Central automatic lubrication is also standard, securing all moving parts of the machine. The grinding wheel spindle is slip-fit and belt driven. The ST variant machines are also equipped with an emergency rebound system to eliminate the risk of ejection or damage to the workpiece due to power failure.

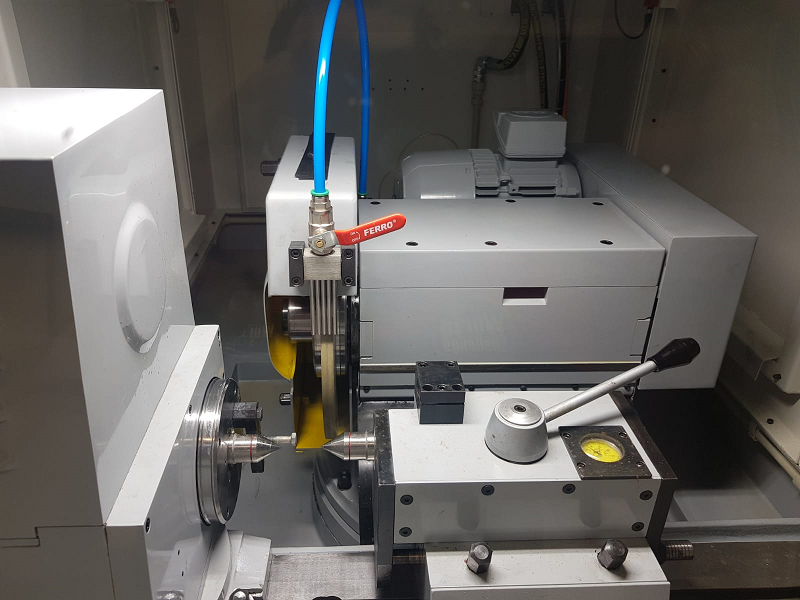

The machine can also be extended with a wide range of equipment. A very desirable option is to equip the machine with a folding arm with fortuna for internal grinding.

Significant simplification of machine operation and reduction of production times is ensured by equipping the machine with a touch probe. With its help, the machine always knows how big the grinding wheel is and what its position is in relation to the workpiece. This significantly speeds up the programming of the machine and increases the programmer’s confidence when adjusting the machine. A side effect is also the minimisation of possible machine crashes due to incorrect adjustment.

In case of higher demands on surface quality, one possible solution is the use of an automatic balancing device. This device dynamically balances the grinding wheel to smooth its operation. Together with the dynamic balancing, it is also possible to use an automatic contact run-in system to reduce the production time to the minimum necessary.

In addition to standard piece and small batch production, we are also able to prepare the machine for large batch production thanks to our extensive experience. It is not a problem to equip the machine with a robotic manipulator using the latest binpicking technology where the machine is equipped with a pallet with loose workpieces, which are correctly oriented and inserted into the machine. The advantage of the robotic manipulator is its variability and the large dimensional range it is able to cover. We also equip the machines with in-process and post-process gauges.